Work Flow

Yoala is a fresh start up yoga carrier company in Australia. They reach out to me to help them shape their products from ideas to physical product.

Introduction to a new project.

Meet with stakeholder to listen about their vision and inspiration for their new products.

From the conversation, they highlight that these new products need to be:

Minimal

Functional

Easy for Production

Research and Initial Concept Proposal

This step helps both designer and client to align their vision and be able to have deeper conversation for:

what components each product need to have based on current market.

how the product should look and feel

what kind of hardware would go well with these products and if we want to do a custom hardware or source from open market.

Sketch Stage

A series of sketches are made to communicate with client on aesthetic and how the product will look and how it will be used. As soon as we nail down the look, the next step is to make prototypes.

Paper Prototype

Paper is the best, most affordable to make samples to test:

How the design will look, since it will be different from 2D sketch to 3D object.

How the product will behave and if there is any roadblock that the paper sample can help to identify.

Sampling

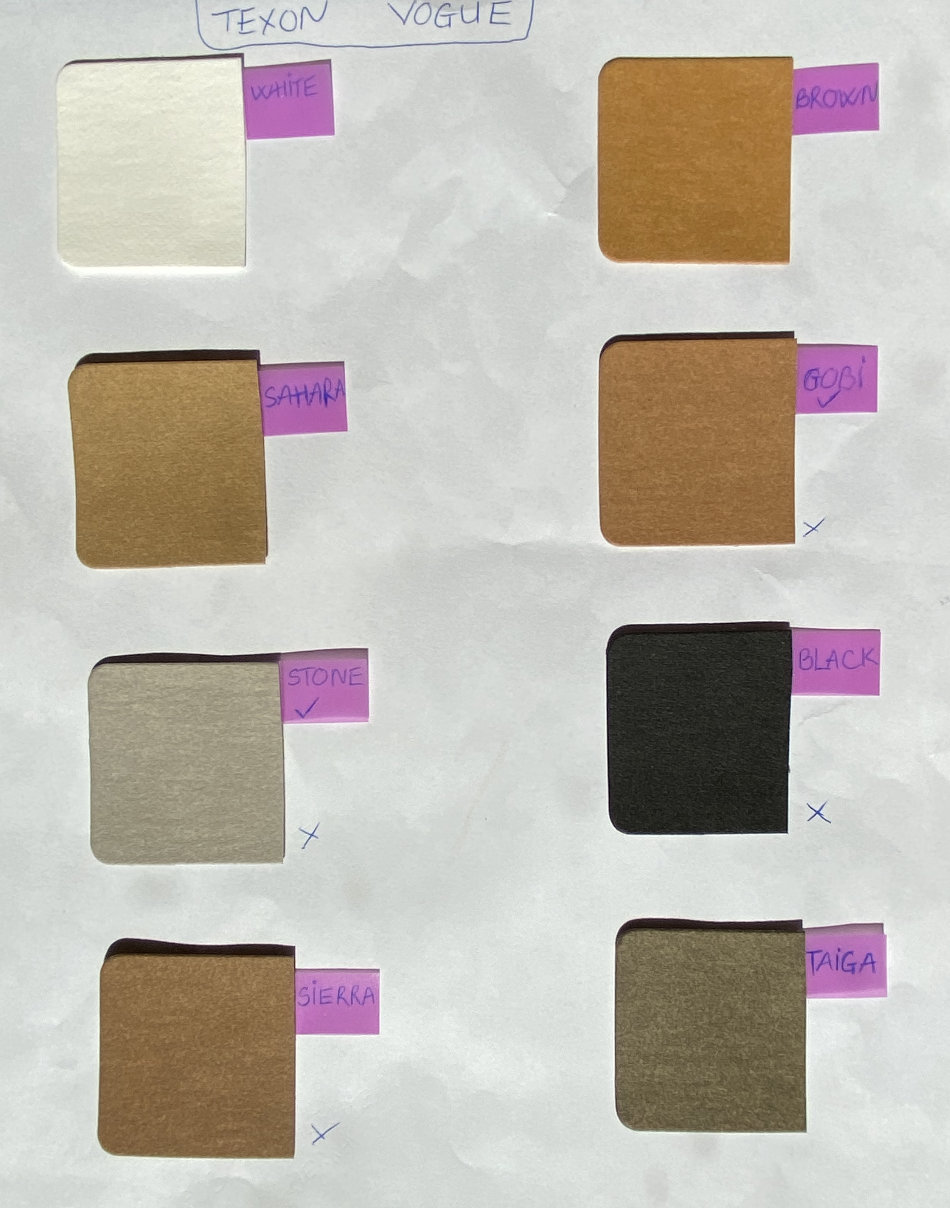

After nailing down the overall based on paper prototypes, the next step is to make real sample using production material: Texon Vogue - Washable paper.

While working on the sample, I also work with client to source necessary hardwares for these products along with assign colors for them as well.

Specification

After getting all the design detail are finalized with client, creating a spec to capture all the details and components for each product is a must.

Lastly, send off all the document to client and send sample to domestic marker for quoting and another round of improvement. Spec will be updated if needed.